Modules

- Discrete manufacturing

- Process Manufacturing

- Mixed-mode manufacturing

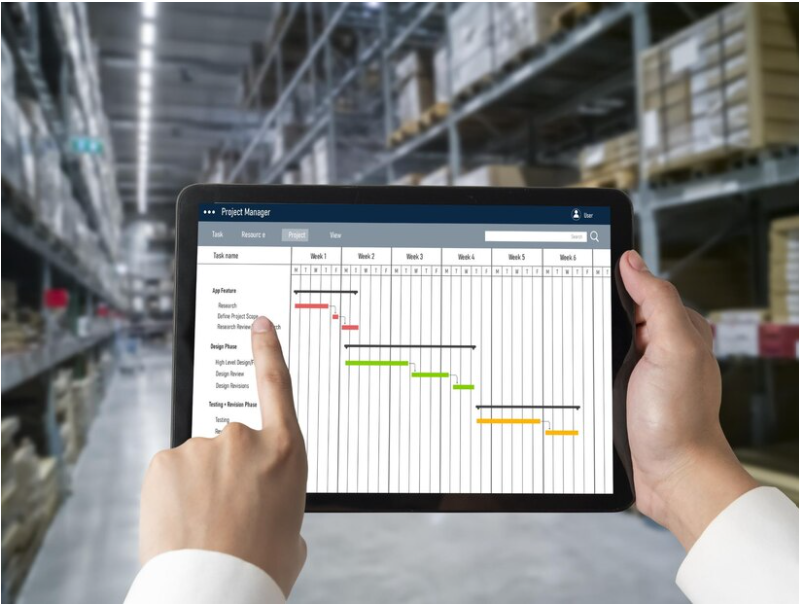

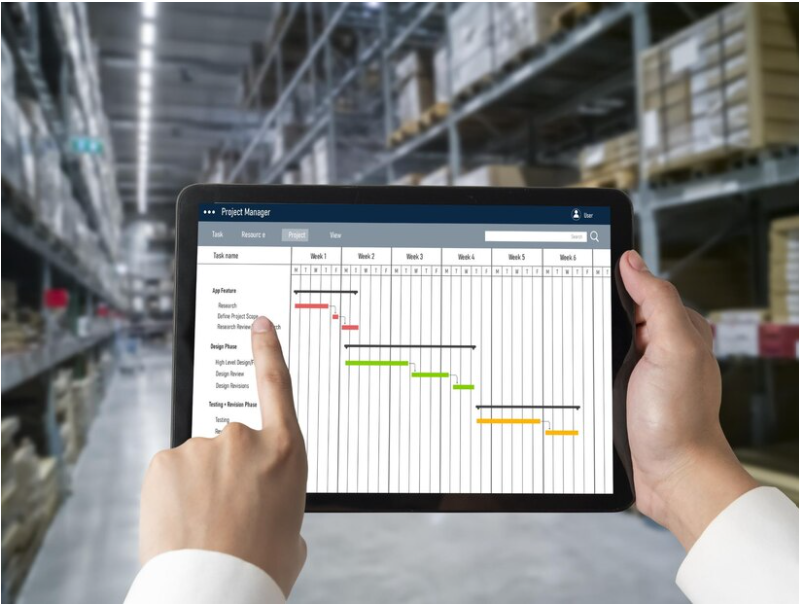

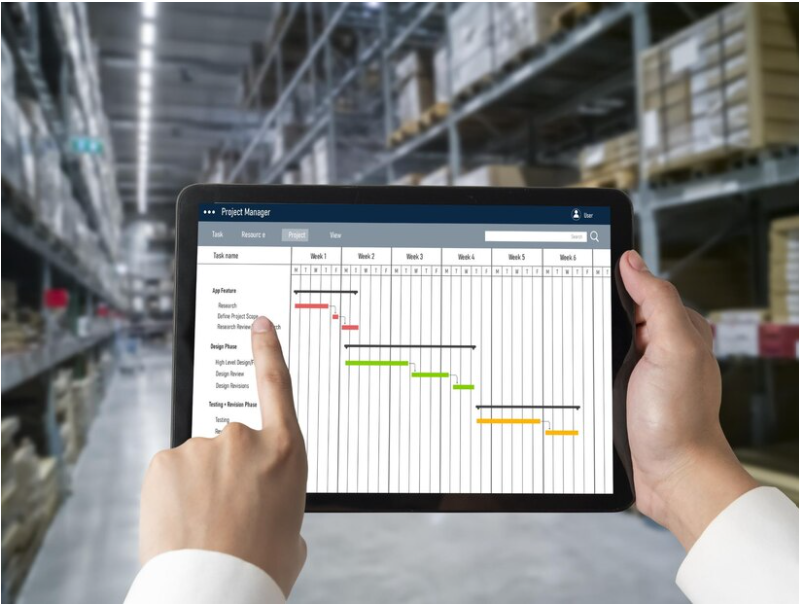

- Production scheduling

- Project-driven supply chain

- Contract manufacturing

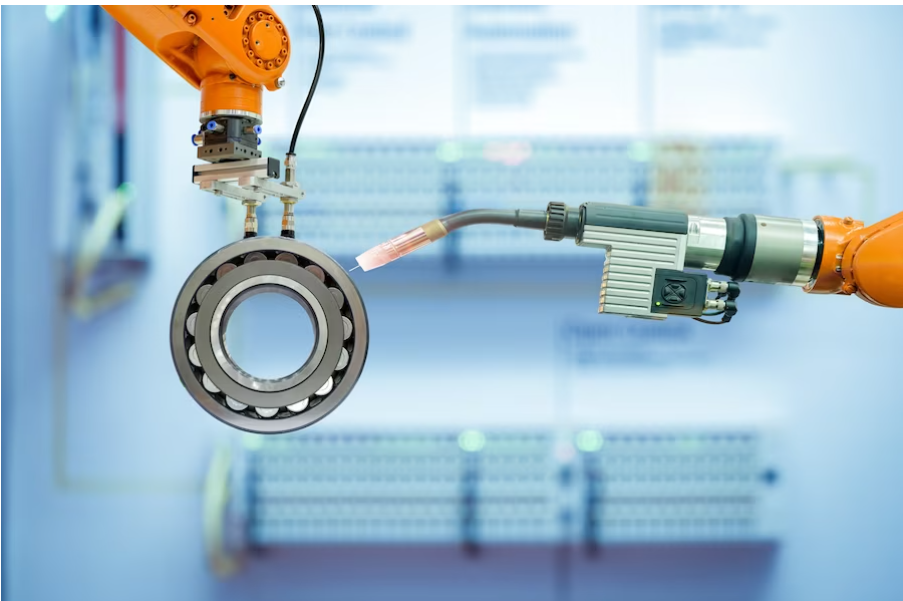

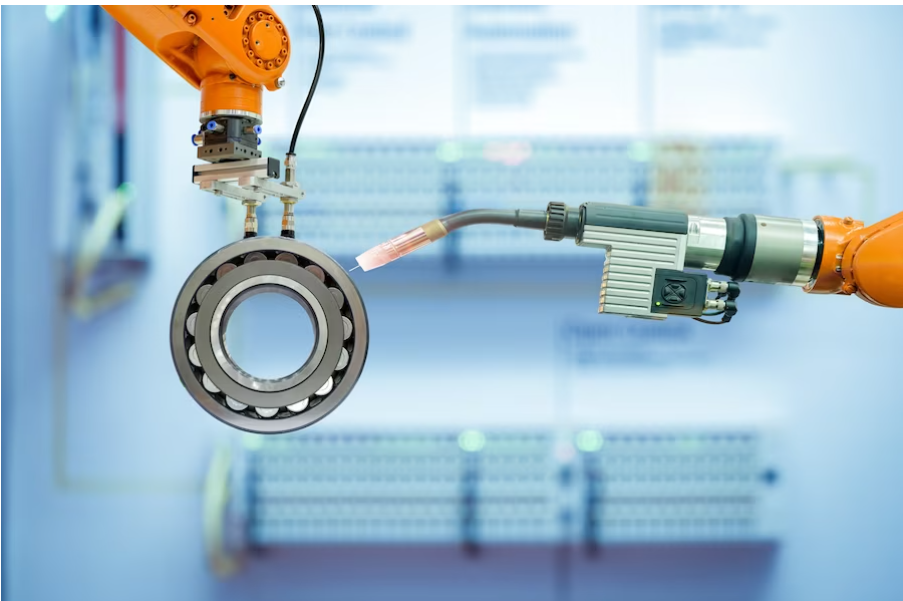

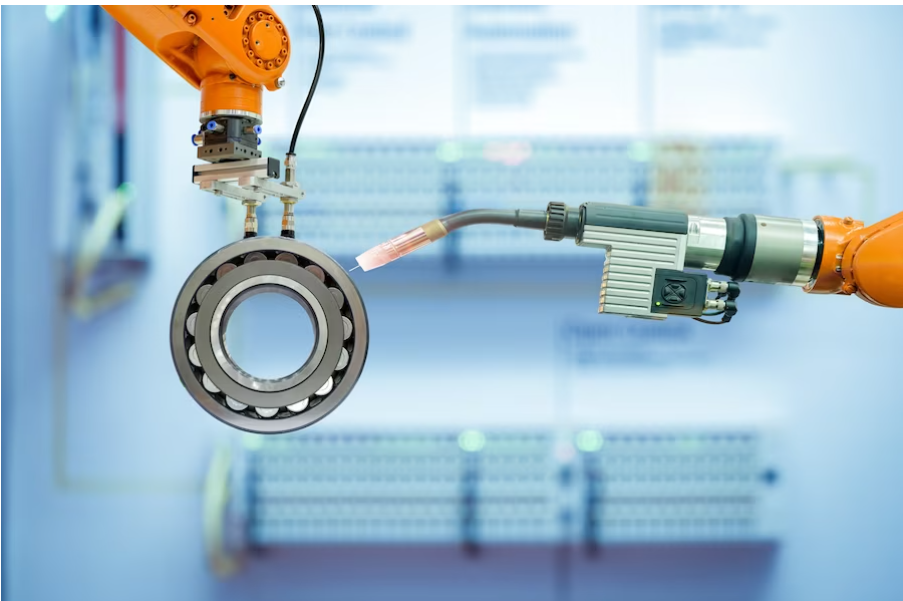

- Connected factory

Is your manufacturing software helping you improve production efficiencies while reducing costs? Learn how Oracle Fusion Cloud Manufacturing helps you streamline your global, mixed-mode manufacturing to make anything, anywhere, with an intelligent, optimized, and integrated solution powered by the Internet of Things (IoT) and Artificial Intelligence (AI).